Parker Polyflex Offshore Hoses

BOP (Blow out prevention) Hose

The BOP (Blowout Prevention) hose is specifically designed for use in the oil and gas industry. It is used to control well pressure during drilling operations and prevent blowouts, which can have catastrophic consequences.

The BOP hose is made of high-quality materials and designed to withstand extreme pressure and temperature conditions. It is a critical component of any drilling operation and must meet stringent safety standards to ensure the protection of workers and the environment.

2390N-04V1x; 1/4" - 7,100 psi Oil & Gas Hose

2390N-08V1x; 1/2" - 6,017 psi Oil & Gas Hose

Inner tube

Polyamide

Reinforcement

Two closed spiral layers and two

open spiral layers of high tensile steel wire

Design Factor

4

Cover

Sea water resistant polyurethane

Standard Colour

Green, Blue, Yellow, Black

Temperature range

-40°F to 131°F (-40°C to 55°C)*

Meets or exceeds the performance

requirements of ISO 13628-5

*Operating temperature limited to 131°F (55°C) by E3 fittings.

2390N-08V12

2390N-08V13

2390N-08V16

2390N-16V12

2390N-16V16

2380N-16V12

2380N-16V16

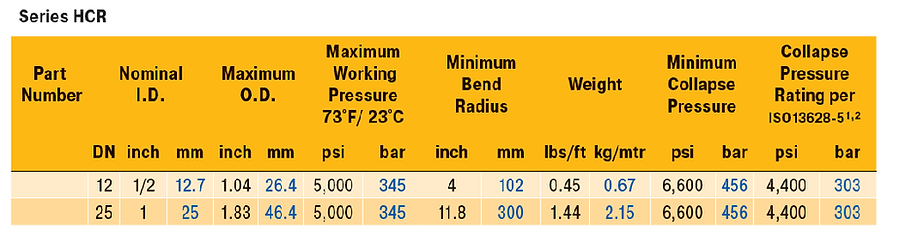

Parflex HCR Hose

High Collapse Resistant Subsea Hose for the Oil & Gas Market

Parflex HCR (High Collapse Resistant) Hose is designed for deep sea applications in the oil and gas industry, where high collapse resistance is crucial.

This hose is made from a thermoplastic material, which provides excellent flexibility and durability in extreme conditions, such as deep sea drilling. The Parflex HCR Hose is also corrosion resistant, making it a reliable choice for offshore operations.

It is suitable for use with hydraulic fluids, chemicals, and water-based fluids, making it a versatile option for various applications.

Features

-

Collapse resistant to 10,000 ft seawater at 1.5 design factor per API 17E

-

Flexible 316L stainless steel interlocking carcass

-

Available in long continuous lengths

-

Seamless polyamide core tube

-

Abrasion and seawater resistant perforated polyurethane cover

-

Compact bend radius

Applications

-

Subsea Hydraulics

-

BOP Stack

-

Well Stimulation

HCRV-16

HCRV-8

Construction

• Carcass: 316L SS • Core tube: Polyamide

• Reinforcement: Aramid Fiber Braid

• Cover: Perforated Polyurethane

Operating Parameters

• Temperature Range:

• -40°F to +131°F (-40°C to +55°C)

• Min. Burst Pressure is 4x Max. Working Pressure

Fittings

-

HV Series - constructed of 316L stainless steel

-

106HV - JIC 37° Female Flare

-

19GHV - Straight Dual Seal

-

1GXHV - Grayloc Hub Connection

Colors

Standard Yellow (-YEL)

Blue (-BLU)

Green (-GRN)

Non-Standard Black (-BLK)

Black Eagle Oilfield Service Hose

Viable alternative to welded pipe

The Black Eagle Oilfield Service Hose is a type of high-pressure hose designed for use in the oil and gas industry. It is specifically engineered to handle the harsh environments and demanding applications of the industry, such as drilling, well stimulation, and production.

The hose is made of high-quality materials and features a high-tensile steel wire braid reinforcement, providing excellent durability and flexibility. It can handle working pressures up to 15,000 psi and is suitable for use with a wide range of fluids, including water, oil, and gas.

Features

-

Up to 30% weight reduction in comparison to R13 rubber hoses - more than 70% in comparison to flexible pipe

-

Long continuous lengths up to 1,000m without splicing (depending on hose type)

Certifications

-

DNV Type Approval P 14038 according to API 7K and API 17J

-

Lower bend radius when compared to composite hose

-

Compact design - smaller O.D. than flexible pipe

-

Inner core has superior chemical resistance

-

ColorGard™ allows for quick recognition of abrasion issues

Applications

-

Cementing • Acidizing • Mud circulation • Water and gas injection

2240N-48V80

2448N-32V80

2580N-32V80

2440N-48V80*

2640N-24V80-15K*

2648N-32V80

2640N-48V80